Slitting Lines

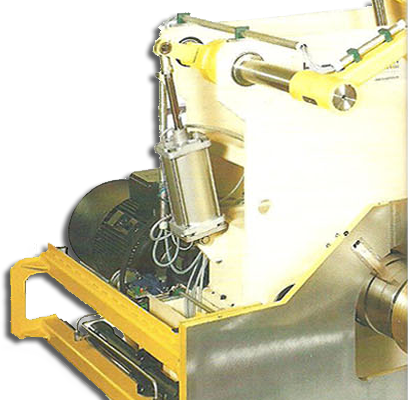

B+S is one of the leading manufacturers of precision slitting lines for cutting and winding also of thin strips and ...

Taiwan

universal cylindrical grinding machine

01.Rawmaterial lnventory

02.Partial view of sawing department

03.Close up of sawing

04.Turning of rotary slitter knives and spacers on CNC machines

05.Vacuum heattreating

06.Rough grinding of rotary slitter knives

07.Straightening of rotary slitter knives

08.I.D. grinding on CNC machines

09.Precision lapping

10.Partial view of lapping department

11.Finish grinding of rubber bonded spacers

12.Final inspection of flatness of rotary slitter knives

13.Final inspection performed in climate controlled Lab

14.Outside diameter grinding

15.Rotary slitter knives and spacers

16.Production storing of rotary slitter knives and spacers

|

MAIN PRODUCTS‧Rotary Slitter Knives ‧Rubber bonded Spacers ‧Spacers ‧Lightweight Spacers ‧DYNABLOC quill assemblies ‧Scraper Blades ‧Cut to length Knives ‧Bending tools ‧Spacers for separator arbors ‧Software for computer assisted set ups(CASKA) |

|

|

CUSTOMERS‧Iron and Steel Works ‧Processors of non-ferrous materials ‧Cold Rolling Mills ‧Steel Service Centers ‧Tube Mills ‧Producers of Profiled Steel ‧Producers of Strapping Materials ‧Producers of Packaging Materials ‧Producers of steel grids ‧Slitting Line Manufacturers |

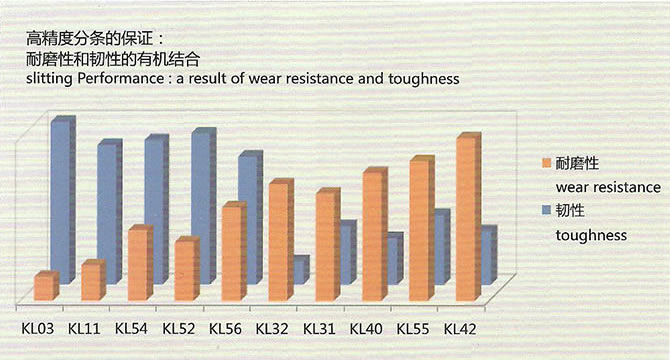

| type of steel | THICKNESS[mm] | ||||

| <0.5 mm | <1.5 mm | <3 mm | <6 mm | >6 mm | |

| cold rolled material | KL31,KL32,KL55 | KL31,KL55 | KL13,KL54 | KL10,KL13 | |

| hot rolled materi | KL10,KL13 | KL03,KL11,KL13 | |||

| stainless steel | KL40,KL55 | KL56 | KL13,KL56 | KL13,KL02,KL61 | |

| silicon steel | KL73,KL74 | KL40,KL55,KL53 | KL13,KL56 | ||

| hardened strip steel | KL40,KL42 | KL55,KL56 | |||

| non-ferrous alloys | KL31,KL32 | KL31,KL32 | KL56 | KL13 | |

|

|

|

|

|

|

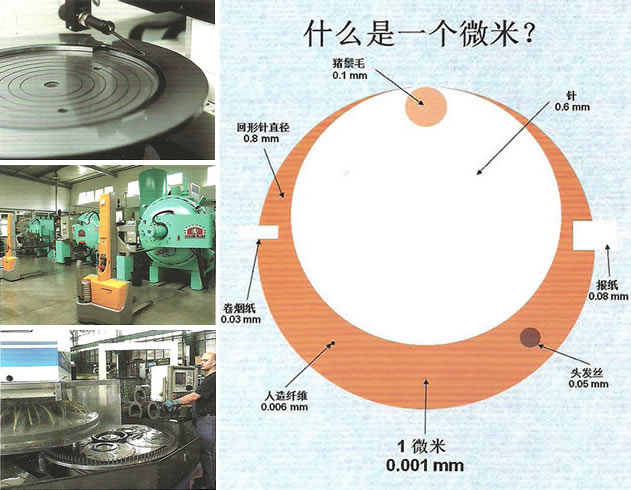

The trend towards higher levels of performance has lead to the deveiopment of ultra precision cutting tools of an accuracy known so for only in the use of precision milling tools.

Thickness tolerances of ±0.001mm (±0.1µm) and surface finishes of Ra 0.1µm have become standard.

For highly demanding accuracies such as required in the splitting process of thinnest alumirium or copper foils it is possible today to manufacture tools in guaranteed thickness tolerance of ±0.5µm.

| O.D. (mm) |

thickness (mm) |

parallelism (mm) |

flatness dependent on thickness(mm) | surface finishes (Ra,µm) |

|||||||

| 厚度範圍(mm) | |||||||||||

| <1 | 1-<2 | 2-<3 | 3-<5 | 5-<10 | >10 | ground | lapped | KSF-polished | |||

| >150 | ±0,0005 | 0,001 | 0,03 | 0,003 | 0,003 | 0,001 | 0,001 | 0,001 | 0,4 | 0,2 | 0,1 |

| >150-250 | ±0,0005 | 0,001 | 0,03 | 0,005 | 0,003 | 0,001 | 0,001 | 0,001 | 0,4 | 0,2 | 0,1 |

| >250-420 | ±0,0005 | 0,001 | 0,05 | 0,01 | 0,005 | 0,002 | 0,002 | 0,002 | 0,4 | 0,2 | 0,1 |

| >420-600 | ±0,0250 | 0,005 | 0,05 | 0,02 | 0,01 | 0,01 | 0,4 | 0,2 | 0,1 | ||

| >600-700 | ±0,1000 | 0,050 | 0,05 | 0,4 | |||||||

|

SOFTWARETo supplement our supply of a complete tooling package as an initial installstion of a slitting line a software package for computer assisted set ups is offered. This software is written tailored to customers needs. As a special service we can determine the tooling needed based on given slitting parameters. |

|

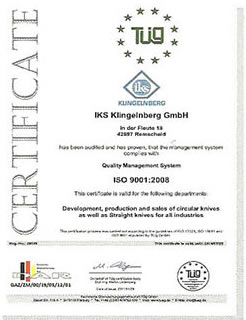

GRINDING SERVICEThe Geringswalde factory can provide accurate regrinding services in a short turn-round time. This offers reliable and professional know how from the machine knife manufacturer without the risk of losing accuracy of the tooling. |

|

RESOURCES PLANNINGWe can provide special containers and boxes for the storage and transportation of high precision tooling or can recommend specialists in the field. |

|

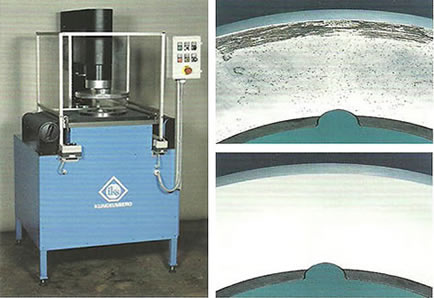

KSF MICROPLANWe offer a device for polishing and cleaning of parallel surfaces of circular tools (knives and/or spacers). The machine has been designed for parts up to 450mm φ and is in conformity with CE-regulations. |

RELIABILITYThe constant modernization of manufacturing equipment over the last 10 years has lead to an increase in capacity, which has clearly reduced the delivery time in favour of our customers. Today, most common knives are available from stock. We aim for our customers satisfaction. |  |

|

SEMINARSIn addition seminars about slitting belong to our range of customer services. In such seminars we are transfering our know-how to our customers and we offer them fully fleched package solutions leading to winning margins and competitive advantages. |

© Copyright CHEN KONG TRADING All Rights Reserved. Design by cynet